(popcorn)

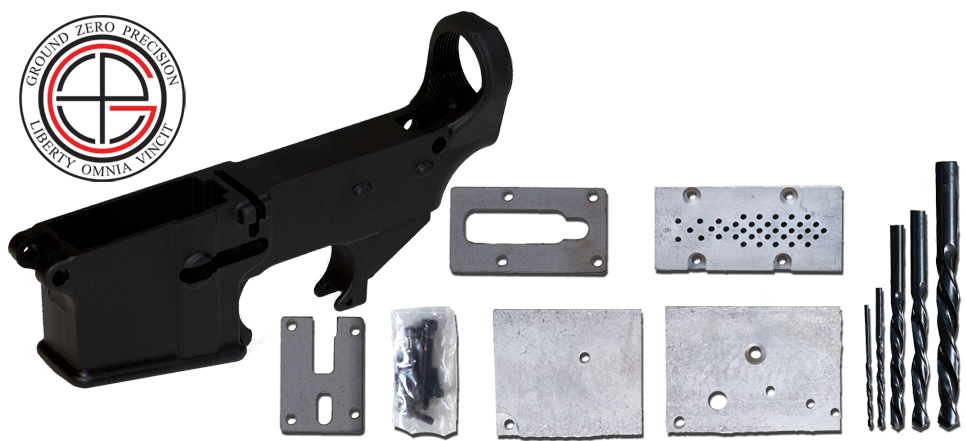

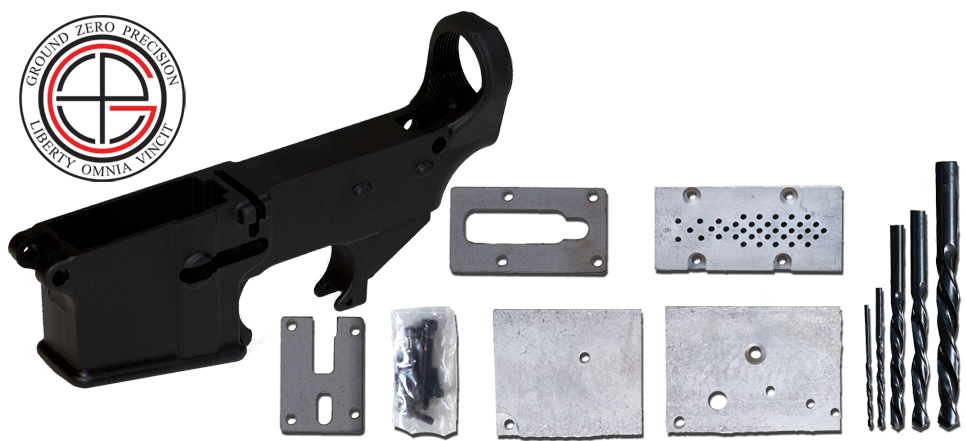

I have a trio of 80%-ers ready to be done, one each for me, my son and my daughter. And a brand-new jig to use on the drill-mill. I have enough parts to do a pistol and almost enough for a carbine. I pick up the occasional piece here or there. Probably build a rifle out of the third one. Time, not money (sort of) is the hold up here...

I will be sure to take pics of the kids building theirs...

John is correct in saying that a complete lower is less expensive. Of course add $20-$30 for an FFL or pay a little extra from a local source (plus tax). Place around here sells Andersons on sale for around $60-$70.

This company (

LINK) does a brisk business in 80s and parts as there are a couple/few mil-spec suppliers in the Daytona area. They are primarily an anodizing co. and also do powder coating but are also an FFL. So they will get in a crate of clear 80s, anodize to suit, then sell. Their prices have risen as they have become more popular. Last time I was there, they let me "test" an upper for them in the snail--poppin' caps in the hood!

I am a long-time anodizing customer but have bought some blems from them among other parts in the past.

A word about 80%-ers... As soon as you cut anything out, it becomes a "gun" with applicable federal regulations. It is "OK" for a citizen to build him or herself their own gun (or three

). Building or helping build more than one and you become a "manufacturer" and are subject to licensing and regulation. The following concern came up regarding building a clear 80%-er then having it anodized after and this came straight from my anodizer (who is also an FFL): Yes, it can be done (ie: anodize a

machined 80%-er) but since it is now a "gun", visual "custody" by the owner must be maintained throughout the anodizing process. And this would not be a common occurrence and probably only reserved for "special" customers.

A serial-numbered (and recorded) completed 80%-er would simply be transferred temporarily to and from the FFL(s). Having a non-anodized machined pocket will not likely affect longevity at all according to them.