I bought my JM pro for my Christmas and Birthday present. I've shot three tactical shotgun matches with it.

During the first, it locked up hard half way through the match. The match director (also a gunsmith) cleared it for me and when I took it home, I found the piston rings had been installed lined up. There was a carbon arrow on the outside of the feed tube.

Thinking I had solved it, I went to another match. It stopped feeding 3/4's of the way through the match.

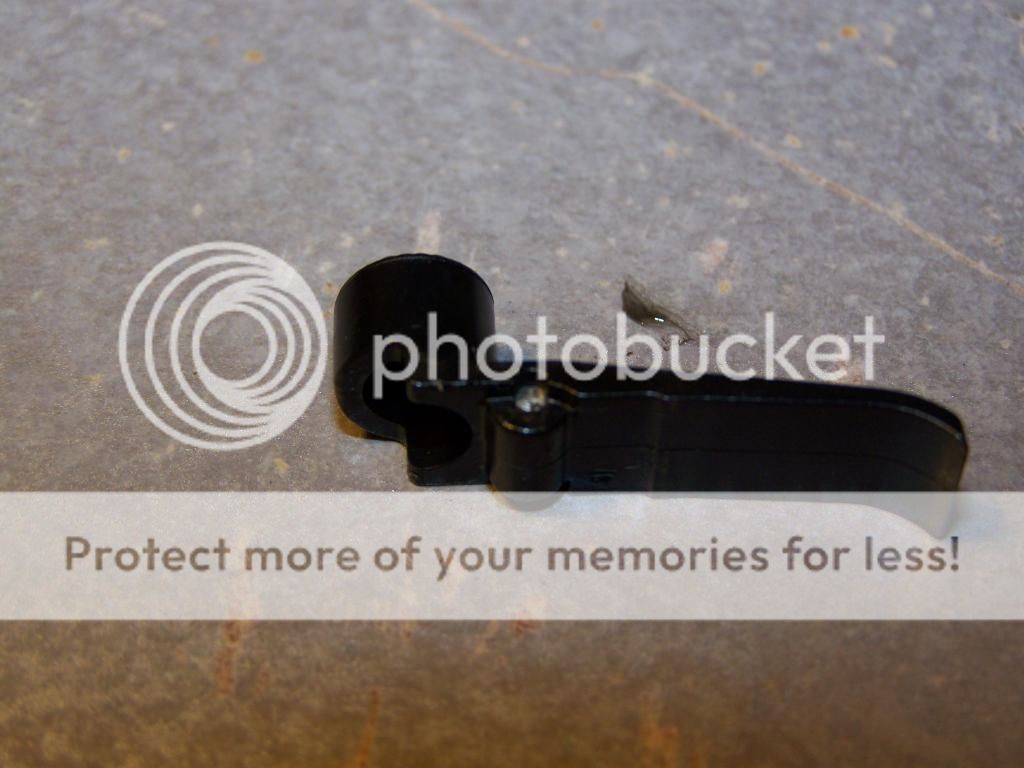

Taking it apart, I found the magazine spring sprung. After I got a new one, I tried cycling rounds through it and they wouldn't cycle. After much gnashing of hands and teeth, and a lot of help from the internet, I took it further apart and found that the forward shell stop pin had broken.

After about 6 weeks waiting for parts, I went to the hardware store, cut off a 1/16" drill bit with a dremel and made a new pin. The gun operated fine for the few rounds I used to make sure that had been the problem.

Mossberg sent me a whole shell stop assembly, but the rear shell stop was too long. I scrounged enough parts from it though, to rebuild it with factory parts (using the old rear shell stop).

Last weekend, It made it all the way through a match...yeah!

Last night though, I tried to practice loading and broke another forward shell stop pin. It seemed to load just fine. I found it on unload.

Is this a common problem? If so, what can the root cause be? I was beginning to build a little trust with the shotgun until last night.

During the first, it locked up hard half way through the match. The match director (also a gunsmith) cleared it for me and when I took it home, I found the piston rings had been installed lined up. There was a carbon arrow on the outside of the feed tube.

Thinking I had solved it, I went to another match. It stopped feeding 3/4's of the way through the match.

Taking it apart, I found the magazine spring sprung. After I got a new one, I tried cycling rounds through it and they wouldn't cycle. After much gnashing of hands and teeth, and a lot of help from the internet, I took it further apart and found that the forward shell stop pin had broken.

After about 6 weeks waiting for parts, I went to the hardware store, cut off a 1/16" drill bit with a dremel and made a new pin. The gun operated fine for the few rounds I used to make sure that had been the problem.

Mossberg sent me a whole shell stop assembly, but the rear shell stop was too long. I scrounged enough parts from it though, to rebuild it with factory parts (using the old rear shell stop).

Last weekend, It made it all the way through a match...yeah!

Last night though, I tried to practice loading and broke another forward shell stop pin. It seemed to load just fine. I found it on unload.

Is this a common problem? If so, what can the root cause be? I was beginning to build a little trust with the shotgun until last night.