Darth

.22LR

Hello all, I'm new here.

I was in the market for a semi-auto 20ga shotgun and, as I was searching, ran across very few reviews of the SA-20 ... well good ones that had any meat to them. I did find one that was very good. The fellow actually went into good detail. So I thought I would join here and give my 2 cents worth.

I bought mine about 2 weeks ago (2nd generation model) and figured I would have to do a TON of work on it as far a clean up and such. As I began to "figure out" how this thing worked, I began to realize that this thing is finished pretty nice. I recently bought a barrel for my 20ga 500CR and I was disappointed with it ... as far as the finish. There were "sharp edges" all over this thing. Not so with the SA-20 ... I was amazed at the things I didn't have to clean up. Most of the edges were smooth.

Some of the first things I did was "figure out" how to dis-assemble it, how it actually functioned and what I might do to make it better.

One of the first things I did was try to remove the magazine tube. It appears in the parts diagram that the tube is threaded into the receiver. I tried heating it and got about a 1/3 turn on it (with a strap wrench) but I saw no "gap" in the receiver area that would indicate it was "coming out" ... so I quit. Perhaps this thing is pressed in ?? I didn't want to damage it because I'm not sure about parts availability.

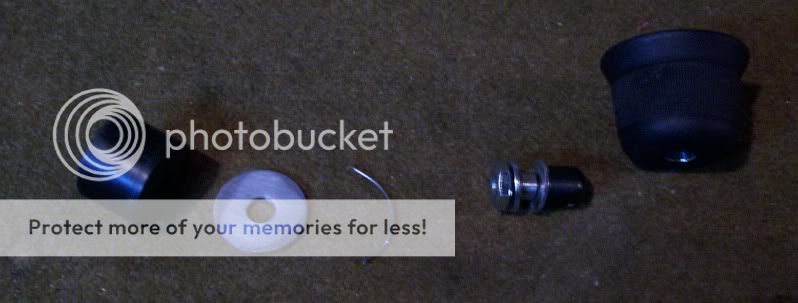

Anyway I pursued another way to access the magazine tube, because I wanted to clean and polish it. What I did was carefully file the ridge off of the other (cap) end and pull the "guts" out. Now my challenge was to find a way to retain the "guts" ... which I did.

I also added a "500 style" swivel attachment to the tube cap and one in the stock.

Overall I'm very impressed with the "fit and finish" on this piece. I haven't shot it yet, but I will soon.

Darth

I was in the market for a semi-auto 20ga shotgun and, as I was searching, ran across very few reviews of the SA-20 ... well good ones that had any meat to them. I did find one that was very good. The fellow actually went into good detail. So I thought I would join here and give my 2 cents worth.

I bought mine about 2 weeks ago (2nd generation model) and figured I would have to do a TON of work on it as far a clean up and such. As I began to "figure out" how this thing worked, I began to realize that this thing is finished pretty nice. I recently bought a barrel for my 20ga 500CR and I was disappointed with it ... as far as the finish. There were "sharp edges" all over this thing. Not so with the SA-20 ... I was amazed at the things I didn't have to clean up. Most of the edges were smooth.

Some of the first things I did was "figure out" how to dis-assemble it, how it actually functioned and what I might do to make it better.

One of the first things I did was try to remove the magazine tube. It appears in the parts diagram that the tube is threaded into the receiver. I tried heating it and got about a 1/3 turn on it (with a strap wrench) but I saw no "gap" in the receiver area that would indicate it was "coming out" ... so I quit. Perhaps this thing is pressed in ?? I didn't want to damage it because I'm not sure about parts availability.

Anyway I pursued another way to access the magazine tube, because I wanted to clean and polish it. What I did was carefully file the ridge off of the other (cap) end and pull the "guts" out. Now my challenge was to find a way to retain the "guts" ... which I did.

I also added a "500 style" swivel attachment to the tube cap and one in the stock.

Overall I'm very impressed with the "fit and finish" on this piece. I haven't shot it yet, but I will soon.

Darth