You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Workin for a livin....

- Thread starter ripjack13

- Start date

megawatt

.270 WIN

Re: Share pics of what you do for a living

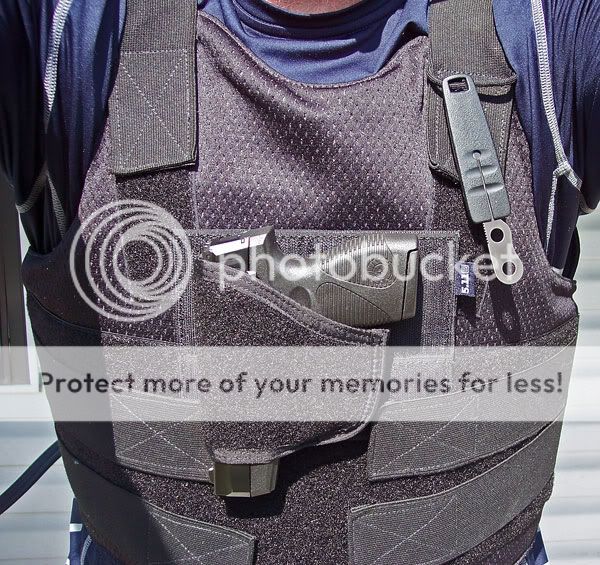

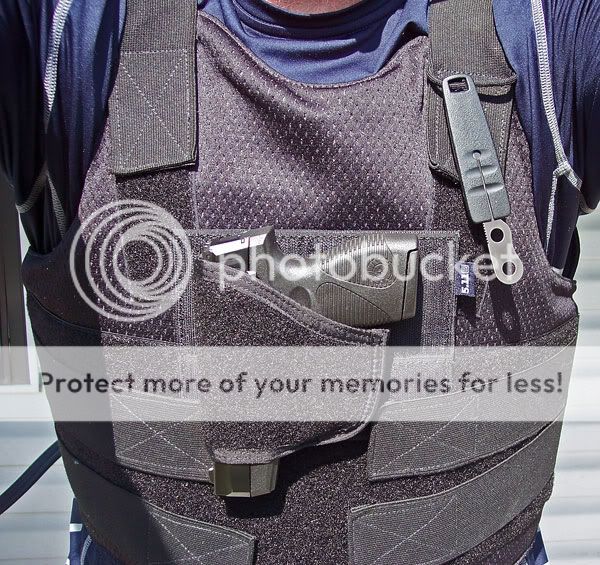

Yup that's what I was talking about. Its under the uniform but still bulky enough to tell they are wearing one.

nitesite said:megawatt said:Here in Vegas every LEO wears body armour 100% is that part of ur uniform?

Do you mean an external vest versus a concealeable Level IIIa vest under the uniform?...........

Yup that's what I was talking about. Its under the uniform but still bulky enough to tell they are wearing one.

It gets really hot and humid here in Alabama and that vest, combined with a dark midnight navy uniform, is pretty awful to wear. But there really is no alternative IMHO. I keep panels of Sham-WOW! inside the carrier next to my undershirt front and back to absorb perspiration and for ease of cleaning. The Sham-WOW! keeps the funk from getting into the ballistic panels which can't be washed. I smell fresh as a daisy most days!!!

Mine is further weighed down my a BUG, although I really don't notice the extra weight.

Mine is further weighed down my a BUG, although I really don't notice the extra weight.

ripjack13 said:Is that a remote I see at the base of the computer? ( on MO of course!!)

Yep, it's for the front and rear radar. Different buttons activate which antenna (Front/Rear), and lock the display when I want to freeze a snapshot. Also there are MENU buttons for selecting sensitivity, audio (doppler whine) , fastest vs. slowest, front target vs. fastest target in a group, etc.

I find that leaving it nestled right there is the most comfortable place to keep it and when I rest my elbow on the center armrest my hand just naturally falls there.

That unit can simultaneously run both front and rear antennas, and pick out the fastest target from each view even if there are multiple cars in the cone, and lock the reading for reference. The remote also chooses whether the reading as taken coming toward me or going in the same direction, and from a stationary spot (me sitting still) or while I'm moving. It's an amazing piece of equipment.

I promise you, with it's "instant ON" there isn't a radar detector in this world that can help you.

ripjack13 said:Today I started making a box for my dog's ashes. Its made of Bocote and Birdseye maple with Gaboon Ebony corner accents. The ends are going to be dovetailed. Not sure yet how I'm going to attach the top & bottom. I'll post up pix later.

ripjack13~

I grieve for your loss of a beloved dog. Building a beautiful wooden urn is a remarkable way to remember your dog. I'll try to remember that when my three go someday.

This thread has me in awe that so many of the members on MossbergOwners have very remarkable lives and careers. Kodiak and rip and oli and mega really earn all the respect. You guys ROCK!!!!!

oli700 said:20 years in wildfire....a couple shots I took...other than the one of me lol

which one is yoooo?

Ripsnortr

20g

This is the view from my "desk" in the shop today.

I am working on a large order to ship out in the next week or two. They are automated wheelchair washers. what you are looking at is the back where the computer and chemical dispensing systems are located. We do everything here in the shop accept the machine work and metal fab/welding.

We do everything from design, prototyping, programing, to actual production so I get my hands dirty in all aspects of the job. Makes my jack-of-all-trades personality very happy.

I am working on a large order to ship out in the next week or two. They are automated wheelchair washers. what you are looking at is the back where the computer and chemical dispensing systems are located. We do everything here in the shop accept the machine work and metal fab/welding.

We do everything from design, prototyping, programing, to actual production so I get my hands dirty in all aspects of the job. Makes my jack-of-all-trades personality very happy.

GirlsLoveGuns2

.30-06

I am a stay at home mom to 4 boys! I'm the maid (laundry, dishes, up keep). I'm the taxi/running errands person, I'm the diaper changer.... Approx 150 diapers a week, And I'm the cook. I'm the "safety police" and doctor when it comes to the guns, bows, arrows, fighting, bo bo's, illness, etc. I'm the animal caretaker. I'm the tickler, jokester, goof off, play time, bath time, and bed time queen. I think it's the hardest job I've ever had.... But it's absolutely worth it when I get paid in hugs & kisses  I love my job!

I love my job!

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Attachments

GirlsLoveGuns2

.30-06

Michelle, I absolutely agree its the hardesat job in the world and never enough credit is given.

I've always told Jenny it was far easier foor me to go to work, and in the event I was home from time to time, I told her I NEEDED to go back to work to get a break... I was laid off for two years and did the Mr. Mom thing. I surprised the house was never on fire while kids are jumping on couches and dogs are eating the beds or whatever. I managed, but not the way Jenny did.

Dinners were lacking, I never made vegetables. Really the only thing I can point to in my defense is trhat no one was ever seriously injured... well except myself, but the kids were ok.

Now theyre all in school. Jenny stayed home for 12 years before goin back to school herself. We're both workin now. (I have pics from my work to post yet!)

The rewards are often seen as the kids grow into the people you have raised them to be. When you see them becoming responsible, accountable and productive. Not that there arent rewards along the way, like when you see the light turn on in their heads as they learn...

Anyhow, sorry for goin on and on... Well done!

I've always told Jenny it was far easier foor me to go to work, and in the event I was home from time to time, I told her I NEEDED to go back to work to get a break... I was laid off for two years and did the Mr. Mom thing. I surprised the house was never on fire while kids are jumping on couches and dogs are eating the beds or whatever. I managed, but not the way Jenny did.

Dinners were lacking, I never made vegetables. Really the only thing I can point to in my defense is trhat no one was ever seriously injured... well except myself, but the kids were ok.

Now theyre all in school. Jenny stayed home for 12 years before goin back to school herself. We're both workin now. (I have pics from my work to post yet!)

The rewards are often seen as the kids grow into the people you have raised them to be. When you see them becoming responsible, accountable and productive. Not that there arent rewards along the way, like when you see the light turn on in their heads as they learn...

Anyhow, sorry for goin on and on... Well done!

Ya I agree about the stay at home gig being the toughest job in the world. It is a true 24/7, 365 days, always on call, everything is an emergency, attention to detail kind of job. My wife and I made the choice to have someone at home for the kids at all time. I was the lucky one ( not sarcastic). One of my most proudest moments was when I took my eldest son (then 5) to buy his first knife. The clerk asked him what he was going to do with it. He responded, "I am going to use it to fix my bike.". The clerk was stunned by the answer. She told me she was expecting him to say he was going to kill something. I told her, it was all in the way they are raised. I've been a stay at home dad for 12 years now.

GirlsLoveGuns2

.30-06

Thank you Oli and Brad (I liked reading your story, glad I'm not alone!).

J.L.... So true about the "always on call, everything is an emergency" part! Some days I have one bleeding from the mouth, while the baby is crawling up the stairs, while the other is throwing raw eggs across the living room, and the other is climbing stuff in the garage to get to the BB gun and then hauling ass out to the back yard to shoot stuff!! EEEEK!! I think I'm losing my mind some days! I only have 2 arms and 2 legs! lol. They take full advantage of that fact that I'm out numbered....even though the oldest isn't even 5 yet, they are smart enough to know!! However, even though I lose it some days and just break down...it is still very rewarding. I loved the story about your son with the knife! It's amazing how much they really do learn from us and "copy" us! You don't realize until a situation like yours where you see it first hand. Great job to you...+1 rep for you

J.L.... So true about the "always on call, everything is an emergency" part! Some days I have one bleeding from the mouth, while the baby is crawling up the stairs, while the other is throwing raw eggs across the living room, and the other is climbing stuff in the garage to get to the BB gun and then hauling ass out to the back yard to shoot stuff!! EEEEK!! I think I'm losing my mind some days! I only have 2 arms and 2 legs! lol. They take full advantage of that fact that I'm out numbered....even though the oldest isn't even 5 yet, they are smart enough to know!! However, even though I lose it some days and just break down...it is still very rewarding. I loved the story about your son with the knife! It's amazing how much they really do learn from us and "copy" us! You don't realize until a situation like yours where you see it first hand. Great job to you...+1 rep for you

The dog in the ice despenser is freakin hilarious!

GirlsLoveGuns2

.30-06

LAZY EYED SNIPER said:The dog in the ice despenser is freakin hilarious!

Yep, he pushes the water thingy to get a drink! He's a hoot and getting smart. He's about 6 months old now! Crazy.

Finally got some pics transferred from my phone!

This is the most recent tank I completed. Its 3/16" 304 stainless steel from top to bottom, with little exception. The exception being pipe fixture are 316 stainless. Welding procedures include spray arc mig (GMAW) and TIG (tungsten inert gas).

The tank is about 14' diameter, the circumference as I recall is like 44' 1/4-ish (outside dimension), it varied a little. The diameter was achieved using a single piece of 3/16" plate 4' x (44' 1/4") then it was rolled to the radius to make the shells. Shells are stacked until we cant go any higher and have to lay the tank down. This one was done in two halves, 4 shells each or 16' long x 14' dia.

The tank was tested a few different ways. Part were vacuum tested for air leaks, then fully ultra-sounded and xrayed, and pressure tested by pumping it full of air to a pre determined psi and then it has to hold for a few days. I passed all tests.

Here is one of the parts I like most, TIG welding the pipe fixtures!

Heres the inside of my half of the tank, you can see the seams which are full penetration welds. First welded (spray arc mig) on the inside, then go outside and grind about half way into the weld, and then fully weld the outside. Thats done at EVERY seam running both the vertical and horizontal! In total, I welded 432 feet of solid weld bead. That doesnt include any of the TIG welds and other components in the tank, like the coil...

Heres my half on the outside, 16' layin down. Theres also some carbon steel on the end to the left which is also MIG welded to the stainless.

This is a shot of the coils. They were rolled in the shop and assembled outside the tank and TIGged.

And finally for now, I took a pic on the inside after the two halves had been joined! This is lookin the 32' length!

I have pics of the tank loaded on the truck but they wont transfer right from my phone...

This is the most recent tank I completed. Its 3/16" 304 stainless steel from top to bottom, with little exception. The exception being pipe fixture are 316 stainless. Welding procedures include spray arc mig (GMAW) and TIG (tungsten inert gas).

The tank is about 14' diameter, the circumference as I recall is like 44' 1/4-ish (outside dimension), it varied a little. The diameter was achieved using a single piece of 3/16" plate 4' x (44' 1/4") then it was rolled to the radius to make the shells. Shells are stacked until we cant go any higher and have to lay the tank down. This one was done in two halves, 4 shells each or 16' long x 14' dia.

The tank was tested a few different ways. Part were vacuum tested for air leaks, then fully ultra-sounded and xrayed, and pressure tested by pumping it full of air to a pre determined psi and then it has to hold for a few days. I passed all tests.

Here is one of the parts I like most, TIG welding the pipe fixtures!

Heres the inside of my half of the tank, you can see the seams which are full penetration welds. First welded (spray arc mig) on the inside, then go outside and grind about half way into the weld, and then fully weld the outside. Thats done at EVERY seam running both the vertical and horizontal! In total, I welded 432 feet of solid weld bead. That doesnt include any of the TIG welds and other components in the tank, like the coil...

Heres my half on the outside, 16' layin down. Theres also some carbon steel on the end to the left which is also MIG welded to the stainless.

This is a shot of the coils. They were rolled in the shop and assembled outside the tank and TIGged.

And finally for now, I took a pic on the inside after the two halves had been joined! This is lookin the 32' length!

I have pics of the tank loaded on the truck but they wont transfer right from my phone...

GirlsLoveGuns2

.30-06

Woah!

This is the big mamba jamba leaving FINALLY!!! It took several hours getting it on the truck having to jockey it around a couple obstacles and getting the trailer properly blocked. We used 2, 10 ton overhead cranes and it weighed in around 17k lbs. Its among the largest tanks we make and too big to stand back up in the shop. We really dont have a specific space too make tanks this big, so we cleared out a bunch of crap in our shear bay which is set aside for for cutting stock plate steel and preparing shells to be rolled. We cut primarily with plasma, natural gas and oxygen torch, or the shear if the metal is light gauge enough. The shear will handle up to 1/4" thick plate.