I have used that Shorty cap several times now, and it really came in handy when I was making tack welds under the car..…I usually keep a long end cap on my torches but I also have a shorty end cap if I need to get in tight. This will require a shorter W. When mine get on the small side I'll swap out to a new 7"-er and keep the stubby for when needed.

I bought another pack of electrodes and sharpened them all up on the grinder last night so I won’t have to get up from the table to grind tungsten.

I was going to buy myself a sleeve to go over my gas hose but that superflex hose is so wonderful that I hate to put a big clunky sleeve on it with zippers and Velcro, double seams and all that stuff.

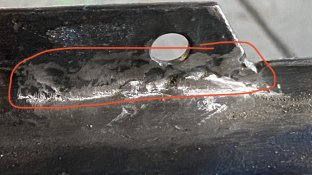

But the nylon covering on my hose has taken some heat damage and I am afraid I’m going to destroy it by dragging it across the hot work or dropping hot metal on it. Maybe I’ll just throw some cheap wire loom on there for now & order some braided Kevlar sleeving.