We just took delivery of a new Mossberg 930 All Purpose 28" with Walnut furniture to have a more 'traditional' looking 930 in the fleet for sporting clays and other 'non-3-gun' purposes. Of course, it immediately got a Marine Spacer Tube and follower upgrade, but things got weird when it was time for an alloy forearm retainer. This is how both the OEM and our own CFR fit this forearm from the factory:

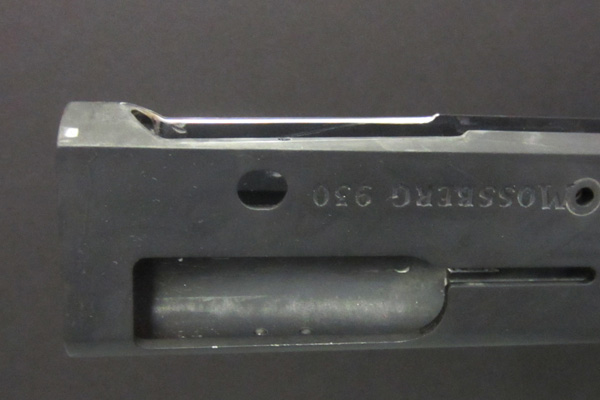

It looks fine from the side and tucked up nicely to the receiver, but a lot more of the Forearm Retainer stuck out than usual, even the factory version did. Here's what it looked like from the top:

Only 1/32" of the OEM or OR3GUN forearm retainers even contacted the retaining ledge inside the forearm. So, after examining all of the contact points it was determined that it was being prevented from seating any further back by the front of the forearm bottoming out on the front of the gas system. Two separate barrels were tried with the same result. So, we took rather drastic measures:

Now, don't combine the items you see on your screen unless you have a background in woodworking and good equipment. Without a pilot, this type of bit may be the scariest 8 seconds you may ever experience without a bull under you. The bit shown was tightened into an extension and put into a drill press, while the forearm was carefully padded and placed in a vise. We first tried a hole saw (with a bit too short of an extension), but the above (when properly balanced) produced good results in removing the material from the front seating surface inside of the forearm. Once the 1.5" diameter ring had been carved by the outer tips of the bit, a dremel with a small cutting wheel (run from the front hole in the forearm) removed the material in between. In all, we removed just under 3/16" worth of material.

Much closer fit. The forearm retainer is now doing its job of retaining the forearm against the receiver. Here's the view from the top:

Now, the tools have been put away as we fight every fiber of our being that wants to ramp that baby for quad loading. So far, it has only had a Nordic +1 magazine extension added to bring it to local Multi-Gun start standards of 5+1 loading. Now we just need to dig out a 1911 and an M1 and go old-school at the next 3-Gun match.

We posted this because we first thought we had a fluke forearm and just dealt with it. Having only seen two wood stocked 930s in the wild, imagine our surprise to see one in the case at a local Walmart the day after we did this. It was a rifled slug gun with the same Walnut furniture and the SAME gap.

So, if you have a wood stocked 930 and have this gap, you now know what is causing it and what can be done about it.

Thanks!

-William

http://www.OR3GUN.com

It looks fine from the side and tucked up nicely to the receiver, but a lot more of the Forearm Retainer stuck out than usual, even the factory version did. Here's what it looked like from the top:

Only 1/32" of the OEM or OR3GUN forearm retainers even contacted the retaining ledge inside the forearm. So, after examining all of the contact points it was determined that it was being prevented from seating any further back by the front of the forearm bottoming out on the front of the gas system. Two separate barrels were tried with the same result. So, we took rather drastic measures:

Now, don't combine the items you see on your screen unless you have a background in woodworking and good equipment. Without a pilot, this type of bit may be the scariest 8 seconds you may ever experience without a bull under you. The bit shown was tightened into an extension and put into a drill press, while the forearm was carefully padded and placed in a vise. We first tried a hole saw (with a bit too short of an extension), but the above (when properly balanced) produced good results in removing the material from the front seating surface inside of the forearm. Once the 1.5" diameter ring had been carved by the outer tips of the bit, a dremel with a small cutting wheel (run from the front hole in the forearm) removed the material in between. In all, we removed just under 3/16" worth of material.

Much closer fit. The forearm retainer is now doing its job of retaining the forearm against the receiver. Here's the view from the top:

Now, the tools have been put away as we fight every fiber of our being that wants to ramp that baby for quad loading. So far, it has only had a Nordic +1 magazine extension added to bring it to local Multi-Gun start standards of 5+1 loading. Now we just need to dig out a 1911 and an M1 and go old-school at the next 3-Gun match.

We posted this because we first thought we had a fluke forearm and just dealt with it. Having only seen two wood stocked 930s in the wild, imagine our surprise to see one in the case at a local Walmart the day after we did this. It was a rifled slug gun with the same Walnut furniture and the SAME gap.

So, if you have a wood stocked 930 and have this gap, you now know what is causing it and what can be done about it.

Thanks!

-William

http://www.OR3GUN.com