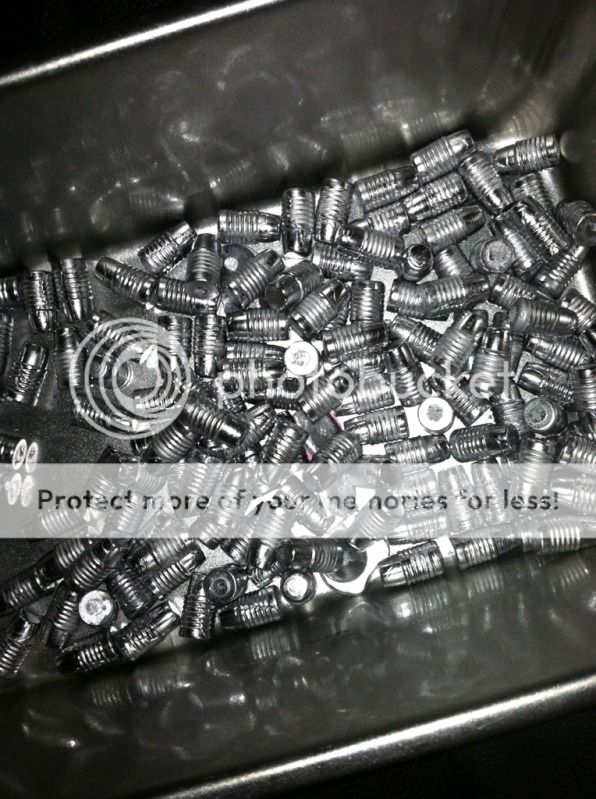

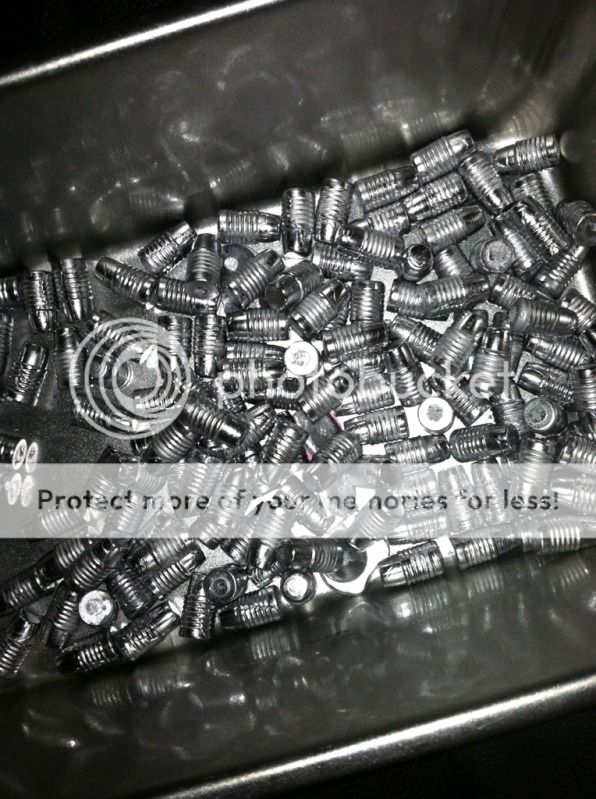

I finally put my casting furnace to work today. It went well, but I wish I got a larger furnace. Most of the bullets came out perfect, but maybe 1/3rd of them look wrinkly. Does my furnace just need to be a bit hotter? And are the wrinkly ones still usable or should I redo them? Anyways, it was quicker than I thought it would be and it was fun. I didn't time myself, but I have 150 bullets (158 gr. LSWC for my new .357 magnum) now and it seemed to take no time at all. I wish I had more smelted lead, so I could keep going while I have the time. I have about 150 lbs of wheel weights I need to get working on. I also have 20 lbs of soft smelted lead.

Big thanks to nitesite for all the instructional videos/links/advice he has posted on here! This was actually lead that he gave to me also.

Big thanks to nitesite for all the instructional videos/links/advice he has posted on here! This was actually lead that he gave to me also.