Tuflehundon has the right idea. You can't feed a shotgun very quickly with gloves on partly because lifters like to eat them. Quick reloading is the name of the game in 3-Gun. Without gloves, a lot of the point of aggressively texturing firearm parts goes out the window and instead becomes a reason to carry bandages with you.

Our Enhanced Bolt Release was designed to address the bigger (or smaller) issues with the factory part. The OEM release has a lot of tilt play that requires a flat, measured press to get the bolt to reliably release. The small OEM release gets missed easily in competition, so we doubled the size and our skirted design prevents the button from simply tilting and not releasing the bolt. Other releases have used extended sections to accomplish the same thing, but they still require drilling and tapping the factory shell stop.

As to texturing, since the part is polished 6061 it can be textured or even further polished by the end user far easier than drilling and tapping for something else. We've done a couple for local guns. Here's how:

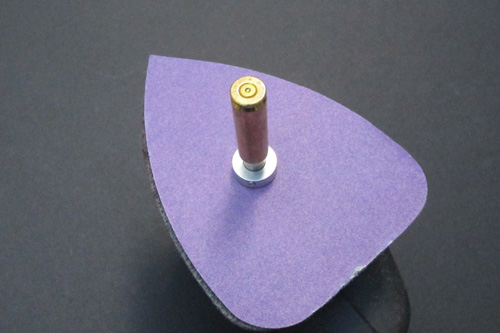

Coincidentally, the inside diameter of our EBR slips perfectly over a fired .308 (or 300 BLK) case mouth. The set screw allows it to stay put. This is handy for securing the EBR for traditional checkering, chucking into a drill press for further polishing or holding onto for easily adding a texture on your own.

A Black & Decker Mouse (or similar vibratory sander) used while quickly running the face of the EBR in a figure-8 pattern with 80-120 grit paper results in a moderately aggressive texture that looks a lot like bead-blasting (top version in picture below).

Here's a close-up of it.

The texture would appear even more random if you combined the Mouse with the EBR chucked into a drill press. You could also round the edge with a few passes of a flat file while it was on the drill press.

This is one of the reasons we eventually end up with different variations of our parts. Not everyone has the same needs. Luckily, this version can be easily textured in raw form.

William

http://www.OR3GUN.com