Re: Review/Issues of my 930 SPX, Sept 2011

nasa said:

The rear sight, not properly clamped to the rail is one culprit. Notice the right side, the rail is not set into the center of the "V" on the clamp. I think if it were properly set on the rail, there is going to be some space between the flat surface or the sight bracket and the rail. May be the difference in the rail between Picatinny and Weaver. If the clamp was centered on the rail with the rail well seated in the "V" of the clamp on each side, it would bring the sight ring closer to center.

Also noted a lot of metal shavings. Looks like it needs a good cleaning and some oil. You can't expect a firearm to be ready to fire right out of the box. Sometimes you might get one with a thick protectant that needs to be removed before use but most of the time it will come with little or no lubrication what so ever.

If it were mine, I might want to see if the Mossberg or the company where I bought it would make it right, but most likely, I would do some tweaking on it, debur it, use some scotch-brite to smooth up a few places, give it a thorough cleaning, lube it up and fire a lot of rounds. Then when I was really happy with how it works, give it another thorough cleaning, re-blue what needs to be re-blued, and go out and shoot it some more.

If you look closely at my rear sight picture again, you will notice the bottom of the sight and the top of the 1913 rail is perfectly paralleled. It wouldn't be parallel if the sight was not set right. What you are seeing is the uneven bevel they put on the right and left edge of the 1913 rail and the shadow of the lighting. It is confirmed on perfect. But if you look closely at the cuts on the top of the receiver and the bottom of the rail, the rail is slightly more to the left; but that would actually cause me to move the windage to the right and not left...so that means the front sight is that much more off.

The metal particles on the receiver you are seeing is brass from the shotgun ammo from the recent time at the range.

This shotgun isn't my first firearm, I always take a new firearm and in this case this shotgun out of the box, read the manual completely at least twice, study the exploded view drawings.

Then I dismantle the shotgun completely to clean out all the factory grease, cosmoline, oil, and metal/cardboard dust shavings/particles. Then I recoat everything with a combination of Militech/Breakfree and let it sit/soak for a few hours and then wipe off all the excess. With the trigger group, I also cleaned it out with a light, soft brush and then coated the assembly with a teflon dry lube.

My shotgun was spotless when I took it to the range for its break in run of mixed

2-3/4" ammo:

30-40 rounds of Fiocchi Low Recoil Slugs (Actual Tested Capacity 6+1)

20 rounds of Fiocchi Low Recoil 00 Buckshot (Actual Tested Capacity 7+1)

10-15 rounds of Remington 1oz Sluggers (Didn't check capacity, more concerned in sighting in)

maybe 60 rounds of Remington/Winchester Universal Target Birdshot ammo (Actual Tested Capacity 7+1)

first thing I noticed after shooting about 6 rounds of the slugs...POI was 6-8" off to the right and 2-3" high @ 50 yards. SPX resting on top of sandbags. I adjusted the front and rear sights until I was happy to get a consistent 4-5" Slug group @ 50 yards on bullseye, then is when I became annoyed the rear sight windage was almost maxed out to the left.

Then rest of the time was used shooting up the ammo...which I was very happy it cycled everything flawlessly and with the occasional rapid fire, full mag dumps.

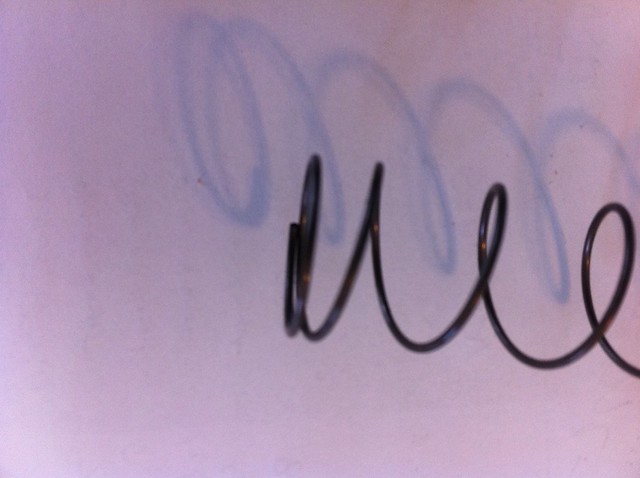

After taking the SPX home from the range, I did a full dismantle again to clean/inspect for wear points; then is where I fully discovered the abnormal wear (Scoring and Ridge) on the Gas Piston area. This is when I started to do a search on the internet on SPX problems and found the first blog on SPX issues by m24shooter dating back to 2009.

This is when I also posted here and introduced myself and the SPX issues I found:

http://www.mossbergowners.com/viewtopic.php?f=5&t=2089

Anycase...I cleaned up and lubed the SPX and adding extra lube to the wear points showing up.

On my 2nd time out to the Range with the SPX, used all the same brands ammo and added Winchester X-pert 1oz slugs to the mix,

about 75 total rounds total used for the day. Near the end of the day, I used the Fiocchi Low Recoil 00Buck and they failed to cycle the SPX every shot; switched back to Remington Standard Clay/Target and Fiocchi Low Recoil Slugs and it performed normal again. Switched back to Fiocchi Low Recoil 00buck and same fail to cycle every shot. I figured it was due to the burr/gouge getting worse, because my first time out with the SPX...I shot more and had no issues.

Took my SPX home and started this blog...so all the pictures and videos taken for this blog is after my 2nd time out to the range. The video of me cleaning the shotgun was done quick to show the issues and reassembly for another member here. I am very a meticulous with my stuff, especially with my firearms...my Sig Sauer P226, I've had since 1988 and have over 8,000-9,000 rounds with only one FTE round (Re-manufactured Range Ammo Round).

In my opinion, having to "Tweak" a factory new product, to do what it should is unacceptable; it shows the product is inferior and company's pride/craftsmanship in providing a "finished" product. "Tweaking" a new product also gives the company reason not to provide warranty service, because you modified it from original specs.

If my SPX was used and out of warranty, sure I would do my own "Tweaks and Mods", but not for a new $600-740 shotgun.

Not sure if all store policies in California are the same, but once you paid and leave with the firearm..it is on you, the buyer; for everything...no exchanges, refunds or returns. (Cancelled purchases incur a 25% restocking fee). Any issues with the product is to be taken care of by the manufacture.

I purchased this Brand/model shotgun based on it being 2009 NRA shotgun of the year and their review (Must have been hand pick and provided by the manufacture) and what I found on youtube. If I had found all the blogs that pertain to this model, I would never have purchased it. I probably would have gone with a Super Nova, 590A1 or 870 in a tactical shotgun and saved my coin for a different brand 12 gauge autoloader. For home defense, my Louisville slugger is more reliable and trusted then to rely on my SPX to feed and function when I need it most.

I am confident that Mossberg will fix the issues with my SPX, from everyone that I speak to or read about; they do stand behind their product.