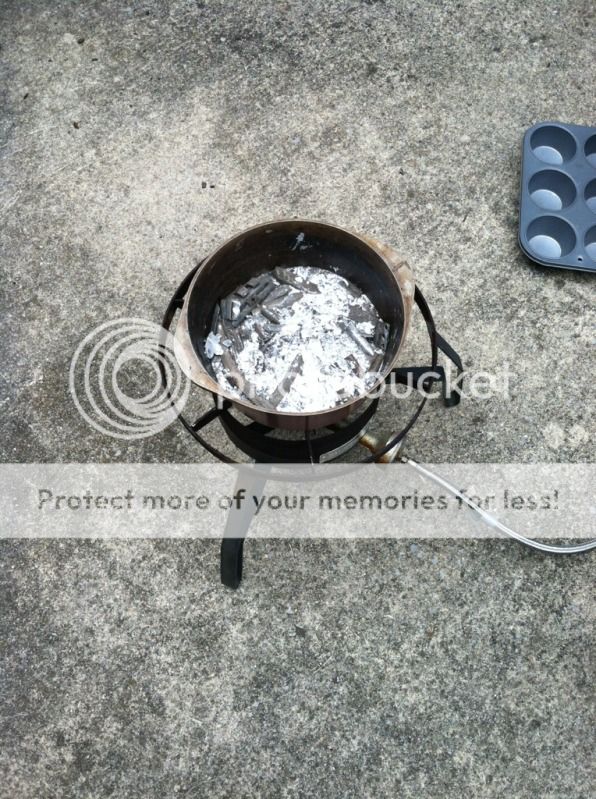

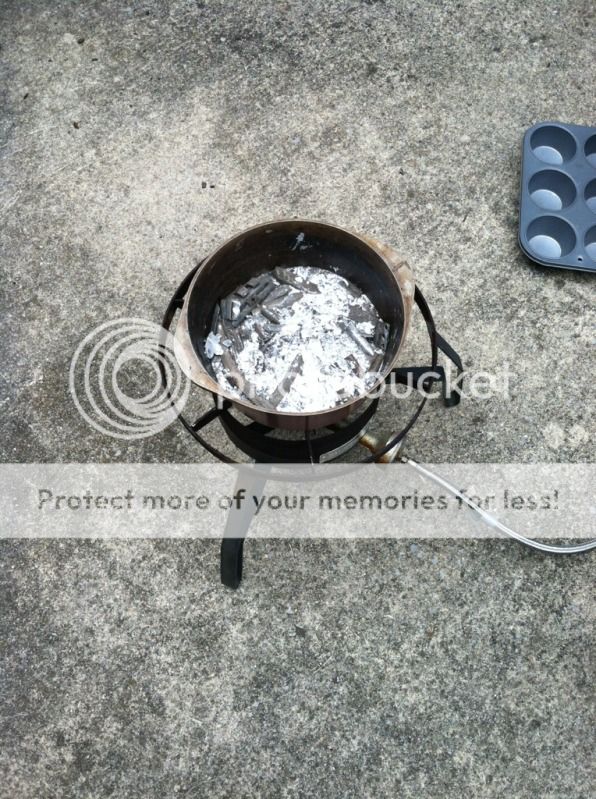

I had some time today to smelt some lead. It went well. I will probably get a spoon with slits in it before I do this again, just because when I used the ladle spoon, I kept dropping stuff back into the pot on accident...

I have a pretty nice burner that got my lead to melting temps very quickly. 50 lbs of lead took me about 30 minutes start to finish.

I have a pretty nice burner that got my lead to melting temps very quickly. 50 lbs of lead took me about 30 minutes start to finish.