You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

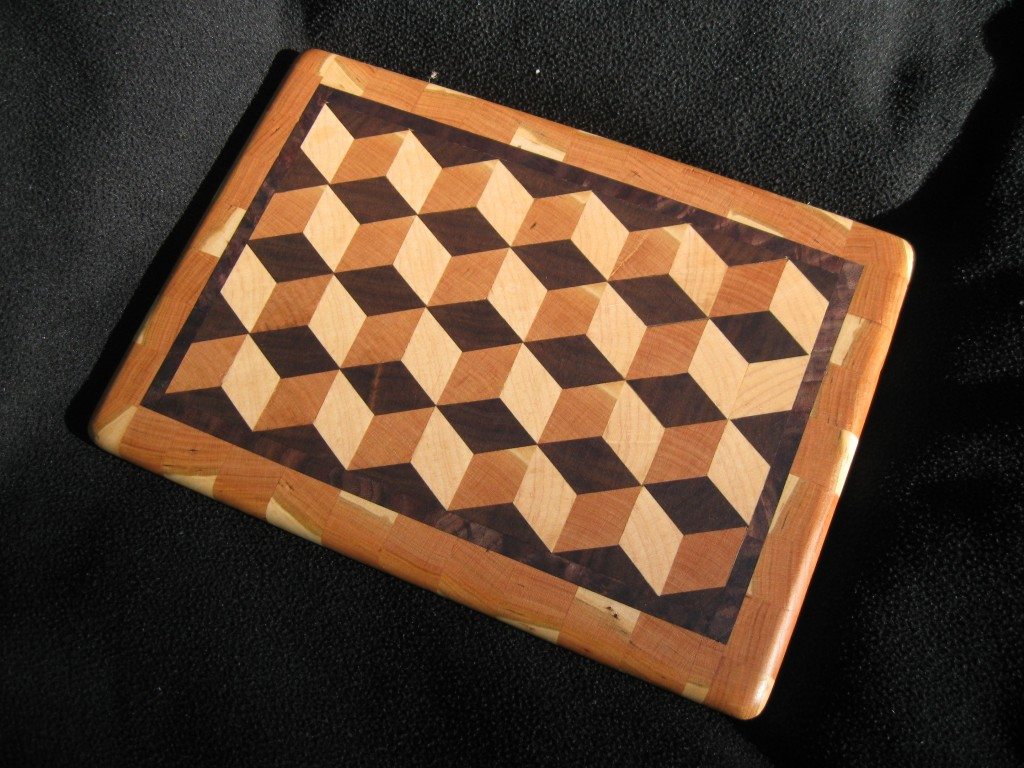

A couple new cutting boards

- Thread starter GunnyGene

- Start date

Gunny......beautiful work! They get coated with butcher block wax?

rdm76mav88 said:Gunny......beautiful work! They get coated with butcher block wax?

Nope. I only use plain mineral oil on cutting boards. Easy and less expensive for me and the customer. I also provide care and feeding instructions with each board. I guess I've made 50 or so of various designs in the last few years. Some gifts, others sold. Easy to make and cooks love them because they're easy on knives.

Btw, here's a excellent video how-to if anyone would like to make their own. You will need a good table saw (not some $200 bench top toy), and a couple other tools, to make good ones.

[youtube]http://www.youtube.com/watch?v=5B8oAJs3sik[/youtube]

John A. said:Those are pretty unique.

Did you use some of the pieces that you cut out from your other jointing projects?

Makes me want to build a chess/checkerboard.

The walnut was some leftovers. The box elder (which is actually a soft maple and very common) was from a tree a I cut a couple years ago. Have about 400bf of it stacked in the garage.

Game boards: Basically the same process - see the video. I have known a few folks who cut a bunch of little blocks and glue them together one at a time.

Not the right way to go about it.

Not the right way to go about it. MikeD said:Those are beautiful...too much so... I'd never be able to use them as cutting boards.

They're made for hard use. The advantage of end grain boards is that they don't show cut marks, they don't harbor bacteria, and your blades will not dull nearly as fast as they do on other types of boards. They are self healing and will last for decades. End grain boards are the Cadillac and Abrams tank of cutting boards. Steel, glass, plastic, or cheap flat grain wood boards don't last and dull knives quickly.

I've sold a couple to local restaurants, and as long as they are kept clean and oiled they will look this good for a very long time.

End grain boards are the only boards I ever recommend.

From the seed on up - grown, harvested, and made in MS, with tools made in the USA. :mrgreen:oli700 said:WOW, really nice job ! and Made in the USA !!

Just thought I'd post some info on the glue I used for these and nearly every other wood project in case anyone is wondering about it.

Titebond II conforms to the ANSI Type II performance standard, which is described on the Titebond website:

Type II testing involves cutting the 6" by 6" assemblies into 2" by 5" specimens, soaking them for 4 hours, then baking the specimens in a 120°F oven for 19 hours. This is repeated for a total of three cycles, and the bonds must not delaminate to pass the Type II specification.

In contrast, Titebond III conforms to the ANSI type I standard:

Type I testing involves cutting the 6" by 6" assemblies into 1" by 3" specimens, boiling them for 4 hours, then baking the specimens in a 145°F oven for 20 hours. They are boiled for an additional 4 hours, then immediately cooled using running water. The specimens are sheared while wet, and the bonds must pass certain strength and wood failure requirements to pass the Type I specification.

BowtieBill

.270 WIN

Those boards look amazing, Gunny.

I know you say they are to be used, but I'd want to hang them on a wall. They are a work of art!

I know you say they are to be used, but I'd want to hang them on a wall. They are a work of art!