Re: My New AR...

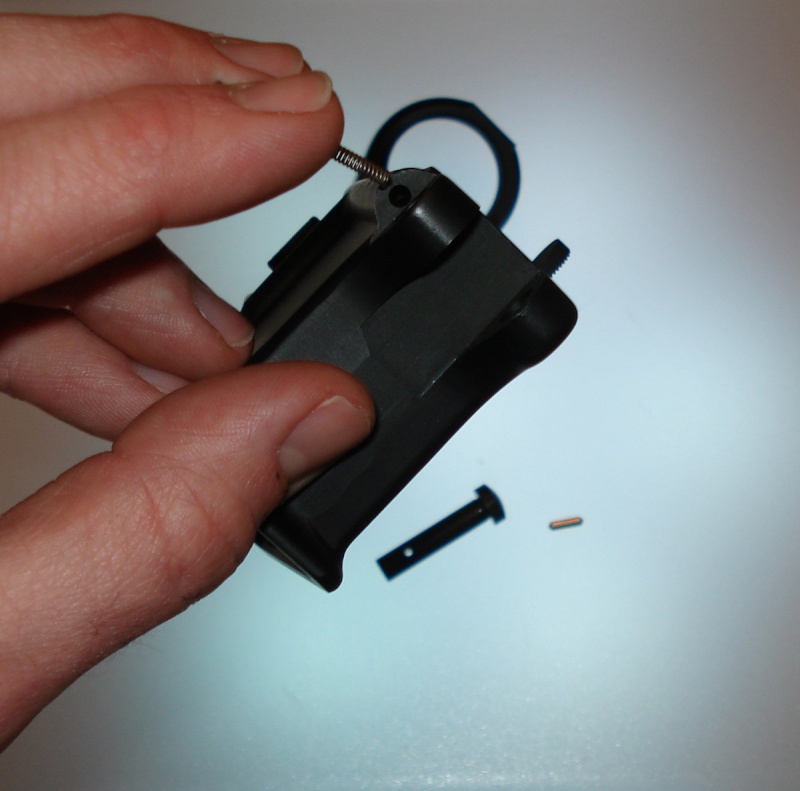

BOLT CATCH ASSEMBLY

PARTS: bolt catch, bolt catch buffer, bolt catch spring, roll pin

TOOLS: 3/32" roll pin punch, 5/32" (or larger) punch

CAUTION: IT IS VERY EASY TO SCRATCH THE RECEIVER ON THIS STEP!

Take special care to make sure pin in in place before driving it, and ensure that it is held securely in place when striking the punch. Fiberglass packing tape - 2 layers thick - taped over the receiver just between the receiver and the punch can help avoid scratching.

•When installing the bolt catch, first drive the roll pin about halfway into the rear hump from the rear of the receiver using roll pin holder. It can be very difficult to get this pin started; you might want to try squeezing the roll pin on one end with pliers or the vise before starting. If you don't have a roll pin holder, then try holding it in place with a pair of needle nose pliers while you drive using a 5/32" punch.

•Install spring in hole on left side of receiver.

•Install bolt catch plunger on top of spring with round portion on top and small end into receiver. Make sure it moves freely in its hole.

•Install bolt catch in receiver; it only fits on one way.

•Use a 3/32" punch to hold the assembly by placing it through the front hump.

•The pin can be driven the rest of the way from the rear as the punch will be pushed out and while holding the bolt catch in correct alignment. (function check as you do it to make sure it's going in correctly)

•Avoid marring/scratching lower by covering receiver with tape, cloth, or other material while you do this.

FUNCTION CHECK

•Verify that the bolt catch functions smoothly and is under tension from the spring.